As boat owners, we’re used to long lead times and expensive bills—especially when it comes to canvas work. Need a new sail cover? That’ll be six weeks (if you’re lucky) and a small fortune. A simple dodger repair? Better break out the credit card. But what if I told you there’s a way to bypass the wait, save serious money, and gain a valuable new skill in the process?

Learning basic canvas work is one of the smartest investments a sailor can make. With a modest upfront investment in tools and a little practice, you can tackle most small projects yourself—saving hundreds (or thousands) of dollars in the long run. And let’s be honest: there’s something deeply satisfying about looking at a finished project and saying, “I made that.”

The High Cost and Long Waits of Professional Canvas Work

Canvas shops do incredible work, but they’re often booked months in advance, especially in coastal areas before peak sailing season. Need a new bimini before summer? Hope you ordered it in February. Even minor repairs can take weeks, leaving you exposed to the elements (or worse—forced to use duct tape as a “temporary” fix).

Then there’s the cost. Custom marine canvas work isn’t cheap, and for good reason—skilled labor, quality materials, and precise workmanship all add up. But for many projects, especially straightforward repairs or simple covers, the DIY route can cut costs by 50% or more.

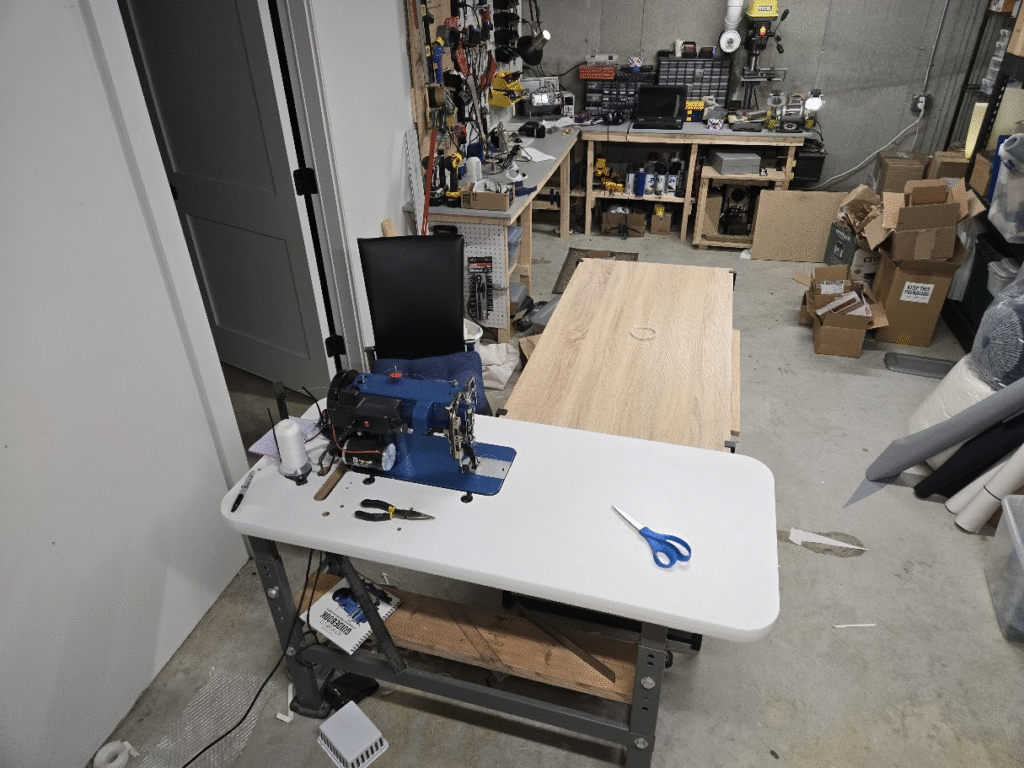

The Sailrite Machine: Entry Level++

If you’re serious about DIY canvas work, a heavy-duty sewing machine is a must. The Sailrite Ultrafeed is the gold standard for boat owners—it’s rugged enough to handle multiple layers of Sunbrella, vinyl, and even sailcloth, yet simple enough for beginners to learn on. There are plenty of other choices for entry level machines – especially on the used market, but for simplicity, portability, maintainability, I think it’s a great choice for a boat owner.

Yes, it’s an investment (around 1,000–1,000–1,500 depending on the model), but it pays for itself fast. Consider this:

- A new sail cover might cost $800-$2000 from a shop. The materials? About $200–$400.

- Dodger window replacement: $400–$800 professionally. DIY? Around $150.

- Custom cockpit cushions? Don’t even get me started on what shops charge.

It’s a classic “guy move” to justify buying a new toy by saying “Think of all the money we’ll save!”—but in this case, it’s actually true. Within one or two projects, the machine pays for itself, and from then on, you’re sewing for pennies on the dollar.

Learning the Ropes: Classes, YouTube, and Apprenticeships

You don’t have to be a master canvasmeister to start. Basic canvas work is surprisingly forgiving—mistakes can often be unpicked and redone without wasting much material. That said, the less you rely on that fact, the more professional your work will look.

Here’s how to get started:

- Take a Class – Many marine stores or community colleges offer basic sewing and canvaswork courses. A few hours of hands-on instruction can save you a lot of frustration. Here in Newport, RI, I was able to take a weekend workshop through IYRS School of Technology & Trades

- YouTube University – Sailrite’s own channel is a treasure trove of tutorials, from sewing straight lines to installing zippers. Other great channels include Canvasworker and Sail Life.

- Intern at a Canvas Shop – If you’re really serious, offer to help out at a local shop in exchange for knowledge. Many tradespeople are happy to teach if you’re willing to sweep floors and handle grunt work.

Projects You’d Never Pay a Shop to Do

Once you gain confidence, you’ll start tackling projects you’d never consider paying a shop for—either because they’re too small, too custom, or just not worth the hassle of outsourcing. On Argon, we’ve:

- Made a cover for our MOB device (it was getting baked in the sun – but no more)

- Made a full set of clip-on covers for the Cap Rails on the perimeter of the deck. This should drastically reduce the UV damage to the brightwork.

- Built a snap-on canvas panel which attaches to a surface in the aft cabin with mesh pockets for “quick-reach” things like lights, tethers, pfds, horns, etc.

In addition to those things, we’ve done a few bigger projects which we would normally go to a shop for:

- Winter Cover Repairs (and a planned total re-build of the winter cover)

- Replaced the dodger windows

- Reworked the attachments for our flexible solar panels when we increased the capacity.

These are all projects that would have cost thousands if done professionally, yet were manageable (and even enjoyable) with some basic skills.

Recent Project: New Sail Cover

Argon’s sail cover was getting pretty long in the tooth. After 10 seasons (including three Caribbean winters), it was quite sun-rotted. It had been to several canvas shops around the Caribbean for repairs and mods. By now, the patches had patches! Along the way, we got a new main sail and switched to a Harken slide system on the mast. The Harken cars are bigger than the previous system so the sail head cover piece never quite fit right. This project gave me a chance to make the adjustments for a better fit. Now, we can actually fully zip up the cover around the front of the mast.

Final Thoughts: Why Every Sailor Should Learn Basic Canvas Work

Canvas work isn’t just about saving money—it’s about self-reliance. When you’re anchored in a remote bay and a seam blows out, you won’t be scrambling to find a shop. When you need a custom solution, you won’t have to wait weeks (or settle for something that almost fits).

Start small, practice on scrap fabric, and build up to bigger projects. Before long, you’ll wonder why you ever paid someone else to do what you can now do better—and for a fraction of the cost.

So, is a Sailrite machine worth it? Absolutely. Will you become a canvas wizard overnight? Probably not. But will you save money, skip the long lead times, and gain a valuable new skill? 100% yes.

Now go sew something.

Leave a Reply